Carbon monoxide (CO) is a highly toxic, colorless, odorless and flammable gas. It is produced when carbon containing materials do not burn completely to carbon dioxide because of insufficient oxygen.

It cannot be detected by our human senses. We cannot see it, smell it or taste it. But unlike many gases, small amounts are extremely harmful to us. Symptoms of carbon monoxide poisoning include headaches, nausea, temporary loss of consciousness that can lead to a coma, weak pulse, respiratory failure and sadly, death.

Carbon Monoxide Solutions

Analox offers a choice of wall mount or portable Carbon monoxide (CO) monitoring solutions.

The Ax60+ CO protects users in plant rooms, parking garages and anywhere that carbon monoxide can collect.

A fixed continuous real-time monitor of carbon monoxide (CO).

A multi-gas analyzer to measure: oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), Volatile Organic Compounds (VOC’s) and Dew Point in compressed air. The unit can be wall mounted or used as a portable system.

The CO Clear is designed to be installed inline on heliox or breathing air compressor arrangements to warn the operator if there is a potential contamination of carbon monoxide before it reaches the user.

The SDA carbon dioxide (CO2) monitor provides reliable carbon dioxide (CO2) monitoring to maintain a comfortable and safe saturation diving chamber.

A digital device for monitoring very low levels of carbon monoxide in breathing air.

Carbon Monoxide (CO)

Why is Carbon Monoxide Dangerous?

Carbon monoxide (CO) is a toxic gas that can’t be detected by human senses as it’s:

- Odourless

- Tasteless

- Colorless

This means that if left undetected by a CO monitor, CO can build up to levels that can cause harm to life.

When you breathe in carbon monoxide, it displaces oxygen within the blood by combining with hemoglobin producing carboxyhemoglobin. This limits the body’s ability to carry oxygen to body tissues including the brain and heart. How quickly this occurs is dependent upon the concentration levels of carbon monoxide being inhaled and how long for.

Symptoms of CO poisoning include:

- headaches or dizziness

- breathlessness

- nausea

- loss of consciousness

- tiredness

- pains in the chest or stomach

- erratic behavior

- visual problems

How is Carbon Monoxide Produced?

Carbon monoxide is a toxic gas that is produced as a byproduct of combustion. It is found in the exhaust of internal combustion engines and in the emissions of industrial processes that involve burning fossil fuels. This is an issue for breathing air compressors that rely on the air in the atmosphere to be clean enough to fill breathing air tanks. One solution that companies use to keep that air clean is a compressed air monitor, such as the CO Clear or the ACG+. Both of these monitors check the air before it makes it to the cylinders, if they detect any CO, they shut off the compressor.

How does carbon monoxide affect the industries Analox work with?

Submarines

It is vital to keep the atmosphere inside a submarine at safe levels, ensuring the safety, health and wellbeing of the crew on board. Monitoring the atmosphere is paramount, especially when it comes to keeping an eye on carbon monoxide (CO). Here is a list of the various ways that CO can be produced onboard:

- Engine exhaust; CO can be produced from the combustion of diesel engines and fuel cells used to power submarines

- Generator exhaust; submarines use generators to produce electricity and CO can be produced as a byproduct of the generators combustion

- Cooking; CO can be produced from cooking activities

- Fire; carbon monoxide can be produced should there be a fire onboard

- Incomplete combustion of chlorate candles can cause a CO leak

Having read the dangers posed by CO in the opening paragraph, it is important to accurately monitor levels of CO in the submarine’s atmosphere to ensure the safety of the crew. However, the submarine environment poses an issue for standard industrial CO monitors as electrochemical sensors are extremely cross sensitive to hydrogen making them unsuitable for use onboard a submarine. But our COSAMS (Carbon Monoxide Submarine Atmosphere Monitoring System) doesn’t see this as a problem. It gets around this issue by using a highly accurate GFC CO sensor and can monitor CO in the atmosphere of a submarine regardless of the hydrogen levels in the air.

For CO submarine atmosphere monitoring, Analox recommends the COSAMS (Carbon Monoxide Submarine Atmosphere Monitoring System), find out more about this product below.

Diving

Just like the atmosphere in a submarine which is solely reliant on tha air onboard, the breathing air used in diving should also be free from any toxic gasses that could cause harm to life. Carbon monoxide can be produced within diving applications in a number of ways including;

- Diving equipment – CO can be produced from the combustion of engines used to power diving compressors, CO can filter its way into a divers breathing air

- Dive boats – carbon monoxide can be produced from the combustion of engines used to power dive boats as well as from generators used to produce electricity

- Rebreather systems – in closed circuit rebreather systems, CO can be produced by the chemical reactions within the system, leading to a buildup of carbon monoxide in the breathing circuit.

Analox recommends the ACG+, the SDA range and the CO Clear, find out more about these products below.

Industrial Applications for CO Monitors

As CO is produced as a byproduct of combustion, this means that CO is produced in different industrial processes, such as:

- Steel production

- Cement manufacturing

- Chemical production

- Burning of fossil fuels

Gas monitoring equipment is used in these settings to detect and measure levels of CO and other pollutants, to ensure compliance with environmental regulations and to protect the health of workers and nearby communities.

Analox recommends using the TEC CO sensor as part of your building management system to provide accurate readings within the area, find out more about this product below.

Why use CO Detectors and Sensors?

Remember carbon monoxide is odorless, tasteless and colorless – it cannot be detected by human senses. Using a CO sensor and monitor will alert you to the presence of carbon monoxide and will offer warnings to rising levels of this poisonous gas.

Analox offers analyzers which are fitted with either an electrochemical CO sensor or a Infrared GFC sensor – so how do these sensors actually work?

Electrochemical CO sensors

Electrochemical carbon monoxide sensors work by using a chemical reaction to measure the concentration of CO gas in air. The sensor consists of three main components: an electrode, a reference electrode and an electrolyte.

- The electrode is coated with a material that reacts with CO gas, producing an electrical current proportional to the amount of CO gas in the air

- The reference electrode provides a stable voltage reference for the sensor

- The electrolyte is a liquid or gel that allows the flow of ions between the electrode and the reference electrode.

When carbon monoxide gas comes into contact with the electrode, it reacts with the material, producing an electrical current. The current is proportional to the amount of CO gas present in the air. The reference electrode and electrolyte maintain a stable voltage and allow the current to be measured, providing an accurate measurement of the CO gas concentration.

Infrared GFC (Gas filter correlation) carbon monoxide sensors

Infrared (IR) based gas filter correlation (GFC) CO sensors work by using the absorption of infrared light by CO gas to measure its concentration. The sensor consists of a light source, an IR filter and a detector.

- An IR light source, typically an LED or a laser, emits IR light into the air.

- The IR filter is a specialized optical filter that is designed to only allow light at a specific wavelength to pass through. This wavelength is chosen to correspond to a specific absorption line for carbon monoxide gas

- The detector, typically a photovoltaic or a pyroelectric, measures the intensity of the light that passes through the filter and the sample of air.

When the IR light passes through the air contaminating CO gas, some of the light is absorbed by the carbon monoxide molecules. The light absorbed is proportional to the concentration of CO gas in the air.

GFC sensors have the advantage of being highly selective and sensitive to CO gas, as well as being less susceptible to interference from other gasses. However they are more complex and usually more costly than the electrochemical sensors.

Cutting-Edge Technology From Analox

We use state-of-the-art technology to develop our gas detection equipment. Our products are designed for maximum accuracy and reliability in any environment. Our products are also easy to use, allowing users to quickly detect carbon monoxide levels in their working area.

- COSAMS is a Carbon Monoxide Submarine Atmosphere Monitoring System that was designed specifically for use on submarines. The COSAMS was built to exacting military standards, ensuring reliability, performance and endurance.

This monitor uses Gas Filter Correlation (GFC) technology (as mentioned above) to analyze the unique properties of CO onboard a submarine. Monitoring CO onboard a submarine is really difficult for standard industrial sensors as they are cross sensitive to hydrogen. The COSAMS uses a GFC CO sensor which targets the exact wavelength of carbon monoxide, this means that the potential for cross sensitivity from other gasses or water vapor is eliminated.

The COSAMS can also provide real time information and alarms to central Submarine Air Monitoring Systems or to the Submarine Platform Management System.

If you would like more information on the COSAMS, click here to view the product page.

- ACG+ is a compressed breathing air monitor. Monitoring oxygen (O2), carbon dioxide (CO2), VOCs (volatile organic compounds), water vapor and carbon monoxide simultaneously. Fitted with the Analox MEC electrochemical sensor, the ACG+ provides continual monitoring ensuring you are compliant with regulations such as EN12021, DEF-STAN 68-284, CGA, CSA and OSHA. In fact the The ACG+ is the only compressed breathing air analyzer currently in use that meets DEF-STAN 68-284 standards for measuring compressed breathing gasses on military vessels.

If you would like more information on the ACG+, click here to view the product page. Or if you would like to see the ACG+ in action, please take a look at one of these case studies, our most recent being a visit onboard HMS protector.

– Joint Services Sub Aqua Diving Centre

– Swagelok

- CO Clear is a simple CO monitor to detect the presence of carbon monoxide in air or nitrox gas compressors. Wall mounted, the CO Clear uses an electrochemical sensor to provide reliable and cost effective continuous monitoring of CO levels.

The CO Clear is designed to be installed inline on an air compressor arrangement to warn the operator if there is a potential contamination of carbon monoxide before it reaches the cylinders/user. Analox recommends that a twin stage regulator is used to reduce the sample pressure.

If you would like more information on the CO Clear, click here to view the product page.

- The SDA range aids a comfortable, safe and successful diving operation. The SDA CO utilizes an electrochemical sensor and provides fast and accurate readings to potentially dangerous levels of carbon monoxide contamination.

Diving system classification societies and industry bodies such as IMCA require/suggest that carbon monoxide levels are maintained at very low levels in a dive system as carbon monoxide is highly toxic. This makes the SDA CO monitor the perfect choice to stay within the requirements.

The SDA CO can be located in sat/dive control or at the compressor. Both the SDA CO and the optional flow panel can be provided as either rack or panel mount.

If you would like more information on the SDA range, click here to view the product page.

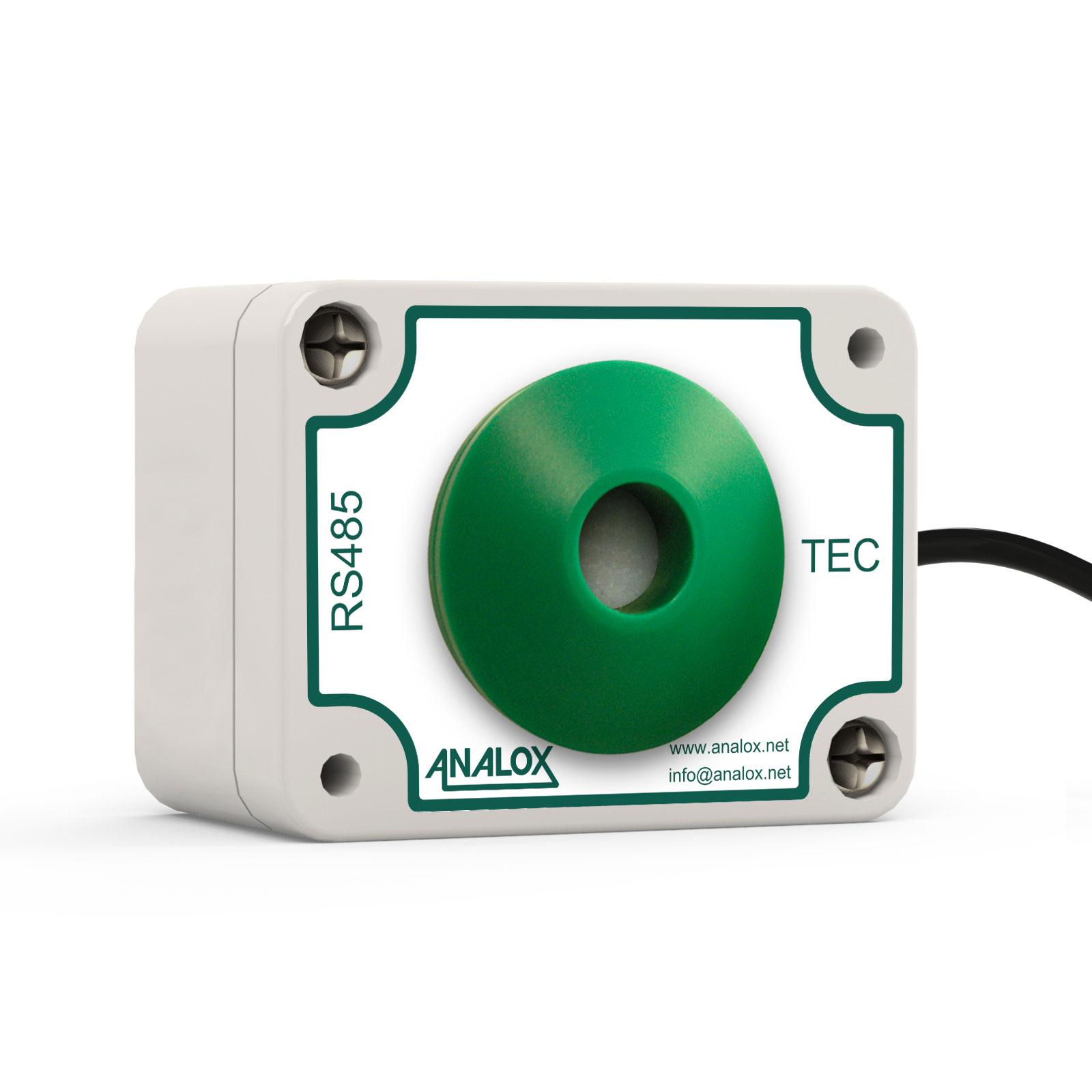

- TEC CO sensor is a robust sensor housed in an IP55 case and has built in temperature compensation and an RS485 digital output via Analox comms protocol. Developed with signal stability it uses a sophisticated electrochemical sensor which provides greater sensitivity than standard.

The TEC CO sensor can be supplied as an original equipment manufacturer (OEM) component for third party systems integration. It can also be incorporated in Analox products such as the SDA CO+ or the ACG+, built specifically for applications measuring sub-ppm gas values.

If you would like more information on the TEC CO, click here to view the product page.

Get Peace of Mind With a Carbon Monoxide Detector

Using a carbon monoxide analyzer or monitor can provide you with peace of mind by ensuring you and your team’s safety from the dangers of CO exposure.

A CO analyzer can accurately measure levels of CO and by ensuring your CO analyzer is regularly maintained you know you and your team are being protected against potentially dangerous levels.

If you have a requirement to monitor carbon monoxide, contact the Analox to discuss the best solution to your problem.

Subscribe to our Analox Newsletter!

Gain exclusive access to the latest news, insights, upcoming product releases in gas safety and efficiency. Be the first to know about our innovative solutions, upcoming events, and expert perspectives. Sign up today!

Fun Fact

Carbon monoxide (CO) is so dangerously toxic that it doesn’t warrant a fun fact.